CONVEYORS

BELT CONVEYOR SYSTEMS

Belt conveyor systems represent a cornerstone technology in the mining and material handling industries, offering efficient and reliable transport of bulk materials over long distances.

These systems consist of a continuous loop of belt supported by rollers, facilitating the movement of materials horizontally, vertically, or on inclined paths.

The benefits of belt conveyor systems are manifold. Firstly, they enhance operational efficiency by automating material transport, reducing the need for manual handling and minimizing downtime associated with loading and unloading processes.

Secondly, these systems optimize space utilization, as they can be configured to navigate complex layouts, including curves and inclines, while maintaining a small footprint.

Additionally, belt conveyors offer versatility in handling a wide range of materials, from fine powders to large aggregates, with minimal spillage or loss.

In terms of safety, belt conveyor systems are designed with features such as emergency stops and protective guards to mitigate risks associated with material handling.

Furthermore, they contribute to environmental sustainability by minimizing energy consumption and reducing emissions compared to alternative transport methods.

Overall, belt conveyor systems play a pivotal role in enhancing productivity, safety, and sustainability in mining and material handling operations, making them indispensable assets in modern industrial settings.

CONVEYOR ROLLERS

Conveyor rollers are fundamental components of conveyor systems and pivotal in facilitating the seamless movement of bulk materials within the mining and material handling industries.

These cylindrical devices, typically made from durable materials such as steel or plastic, provide support and guidance to conveyor belts, ensuring smooth and efficient transport of materials across various distances and terrains.

The benefits of conveyor rollers are multifaceted.

Firstly, they contribute to enhanced operational efficiency by reducing frictional resistance between the belt and the supporting surface, thereby minimizing energy consumption and extending the lifespan of conveyor systems.

Additionally, conveyor rollers are designed to withstand heavy loads and harsh environmental conditions, ensuring reliable performance in demanding industrial settings.

Moreover, conveyor rollers play a crucial role in minimizing material spillage and down

time by maintaining proper alignment and tension of conveyor belts, thereby optimizing material handling processes.

Furthermore, their modular design allows for easy installation, maintenance, and replacement, resulting in reduced downtime and operational costs over the long term.

In terms of safety, conveyor rollers are engineered with features such as sealed bearings and precision machining to prevent accidents and injuries associated with material handling operations.

Overall, conveyor rollers represent indispensable components in mining and material handling applications, facilitating efficient, safe, and cost-effective transportation of bulk materials.

OTHER INDUSTRIAL EQUIPMENTS

CENTRIFUGE

Centrifuges are essential devices utilized in mining and material handling industries to separate solid particles from liquids or slurries based on their density differences through centrifugal force.

These precision-engineered machines employ high-speed rotation to generate centrifugal acceleration, causing heavier particles to migrate outward and settle while lighter components remain suspended or are expelled.

The benefits of centrifuges in industrial applications are significant.

Firstly, they enable efficient and precise separation of valuable minerals or materials from impurities, enhancing the overall yield and quality of processed materials. This contributes to increased profitability and resource utilization in mining operations.

Secondly, centrifuges offer versatility in handling various types of materials and can accommodate a wide range of particle sizes and densities, making them suitable for diverse applications within the mining and material handling sectors.

Furthermore, centrifuges promote environmental sustainability by facilitating the recovery and recycling of valuable resources from waste streams or byproducts, minimizing waste and reducing environmental impact.

In terms of operational efficiency, centrifuges are designed for robust performance and reliability, with advanced features such as automatic control systems and self-cleaning mechanisms, reducing downtime and maintenance requirements.

Overall, centrifuges play a critical role in optimizing processes, maximizing resource utilization, and ensuring sustainable operations in mining and material handling industries, making them indispensable assets for modern industrial enterprises.

SCREENS

Industrial Screens are essential components utilized in a variety of industries for the classification, separation, and filtration of materials based on size, shape, or other physical properties. These screens consist of a series of meshed or perforated surfaces arranged to allow the passage of desired particles while retaining larger or unwanted materials.

The benefits of industrial screens are manifold. Firstly, they enable precise control over particle size distribution, ensuring consistent product quality and enhancing process efficiency. By efficiently separating materials into different size fractions, industrial screens facilitate downstream operations such as sorting, conveying, and packaging.

Moreover, industrial screens play a crucial role in removing contaminants or foreign objects from raw materials or process streams, thereby improving product purity and safety. This is particularly important in industries such as food processing, pharmaceuticals, and wastewater treatment.

Additionally, industrial screens offer versatility in application, with customizable designs to accommodate specific process requirements and material characteristics. They can be constructed from various materials such as stainless steel, polyurethane, or woven wire mesh, ensuring compatibility with different operating environments and applications.

Furthermore, industrial screens contribute to cost savings and operational efficiency by reducing downtime associated with equipment maintenance and minimizing product loss or waste. Their robust construction and durable materials ensure long-term reliability and performance in demanding industrial environments.

Overall, industrial screens are indispensable tools for optimizing processes, enhancing product quality, and ensuring regulatory compliance across a wide range of industries, making them essential components of modern engineering solutions.

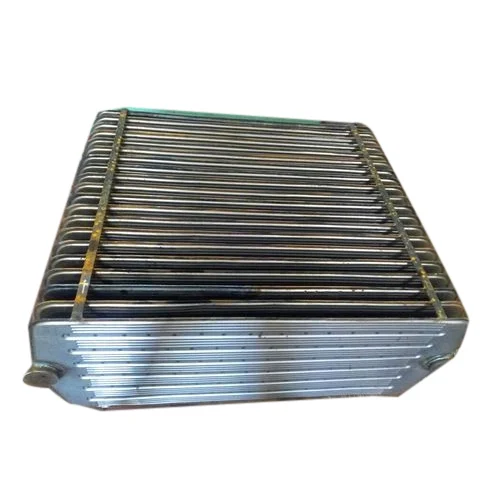

DEWATERING SYSTEMS

Dewatering systems are integral components utilized across various industries for the removal of excess water or moisture from solid materials, sludges, or slurry streams. These systems employ mechanical or chemical processes to separate water from solids, thereby improving material handling, processing efficiency, and waste management practices.

The benefits of dewatering systems are significant and multifaceted. Firstly, they enhance process efficiency by reducing the moisture content of materials, resulting in faster drying times and increased throughput in downstream operations such as drying, transportation, or disposal.

Moreover, dewatering systems play a crucial role in minimizing the volume and weight of waste materials, thereby reducing storage and disposal costs while improving environmental sustainability. By concentrating solids and reducing the volume of liquid waste streams, these systems facilitate the recovery and reuse of valuable resources, promoting efficient resource management practices.

Additionally, dewatering systems contribute to improved product quality and consistency by removing excess water from raw materials or intermediate products, resulting in enhanced product performance, stability, and shelf life.

Furthermore, dewatering systems offer versatility in application, with a range of technologies and configurations available to suit specific process requirements and material characteristics. Whether employing methods such as filtration, centrifugation, or mechanical pressing, these systems can be tailored to meet the unique needs of diverse industries, from mining and construction to wastewater treatment and food processing.

Overall, dewatering systems are essential tools for optimizing processes, reducing costs, and ensuring environmental compliance across a wide range of industries, making them indispensable components of modern engineering solutions.

HYDROCYCLONES

Hydrocyclones are pivotal devices employed across various industries for the separation and classification of solid particles from liquid suspensions or slurries based on their size, density, and shape.

These cylindrical vessels utilize centrifugal force generated by high-speed rotation to induce particle separation, with heavier particles migrating towards the outer wall and lighter particles towards the center, where they are discharged.

The benefits of hydrocyclones are manifold. Firstly, they offer highly efficient and precise particle separation, enabling the removal of fine solids from liquid streams with minimal energy consumption. This enhances process efficiency and product quality while reducing the need for downstream filtration or clarification steps.

Moreover, hydrocyclones facilitate the concentration and recovery of valuable materials from process streams, thereby maximizing resource utilization and reducing waste. By effectively removing solids from liquid suspensions, they contribute to the optimization of downstream processes such as dewatering, thickening, and solid-liquid separation.

Additionally, hydrocyclones are compact and modular in design, making them suitable for integration into existing process systems and installations. Their simple operation and low maintenance requirements further enhance their appeal for industrial applications.

Furthermore, hydrocyclones are versatile tools capable of handling a wide range of materials and operating conditions, from mining and mineral processing to wastewater treatment and oil and gas production.

Overall, hydrocyclones play a crucial role in improving process efficiency, product quality, and resource utilization across diverse industries, making them essential components of modern engineering solutions offered by Adroit Engineering.

GEARS & SPARE PARTS OF THE ABOVE EQUIPMENTS

WE ALSO PROVIDE THE GEARS AND SPARE PARTS OF ALL THE ABOVE EQUIPMENTS

PU PRODUCTS

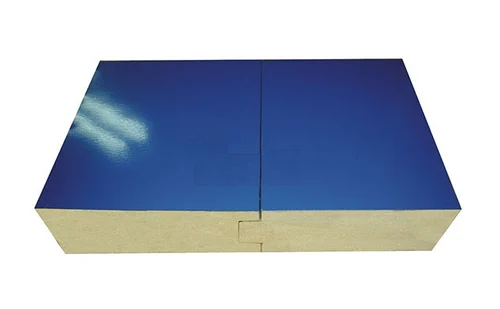

FLAT PANELS

Polyurethane (PU) flat panels are innovative components widely utilized across industries for various applications, offering exceptional durability, versatility, and performance. These panels are fabricated from polyurethane, a highly resilient and abrasion-resistant material, and are designed to withstand harsh operating conditions while delivering superior performance and longevity.

The benefits of PU flat panels are manifold. Firstly, their rugged construction and abrasion resistance make them ideal for use in high-wear environments, such as mining, aggregate processing, and bulk material handling. They provide reliable protection against wear and damage, reducing downtime and maintenance costs associated with equipment failure or replacement.

Moreover, PU flat panels offer excellent impact resistance and flexibility, allowing them to adapt to dynamic operating conditions without compromising performance. This ensures consistent product quality and process efficiency, even in challenging environments.

Additionally, PU flat panels are lightweight and easy to install, facilitating quick and cost-effective maintenance and replacement procedures. Their modular design allows for seamless integration into existing equipment and systems, enhancing operational flexibility and scalability.

Furthermore, PU flat panels are resistant to corrosion, chemicals, and temperature fluctuations, making them suitable for a wide range of industrial applications, including screening, dewatering, and filtration.

Overall, PU flat panels represent a versatile and reliable solution for industries seeking to improve productivity, efficiency, and reliability in their operations, making them a valuable offering from Adroit Engineering.

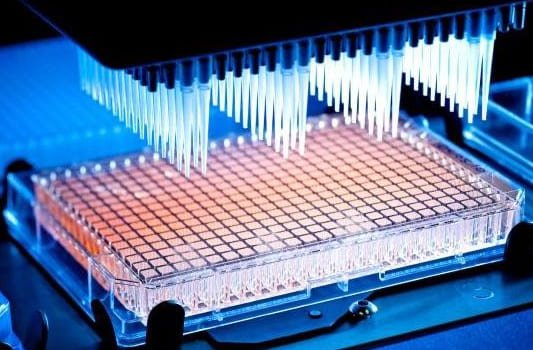

SIEVE PANELS

Polyurethane (PU) sieve panels are advanced components utilized across industries for efficient and precise particle separation and classification in screening applications. These panels, fabricated from polyurethane material, exhibit exceptional durability, resilience, and wear resistance, making them ideal for demanding industrial environments.

The benefits of PU sieve panels are significant. Firstly, their high abrasion resistance and durability ensure prolonged service life and minimal maintenance requirements, resulting in reduced downtime and operational costs for industrial processes. They provide reliable and consistent performance in screening applications, even in high-wear conditions such as mining, quarrying, and aggregate processing.

Moreover, PU sieve panels offer superior screening efficiency and accuracy, enabling precise separation of particles based on size, shape, and composition. This enhances product quality and consistency while optimizing process performance and throughput.

Additionally, PU sieve panels are lightweight and easy to handle, allowing for quick and hassle-free installation, maintenance, and replacement procedures. Their modular design facilitates seamless integration into existing screening equipment and systems, enhancing operational flexibility and productivity.

Furthermore, PU sieve panels are resistant to corrosion, chemicals, and temperature fluctuations, ensuring reliable performance in diverse industrial applications, including dry screening, wet screening, and dewatering processes.

Overall, PU sieve panels represent a cost-effective and reliable solution for industries seeking to improve screening efficiency, product quality, and operational reliability, making them a valuable offering from Adroit Engineering.

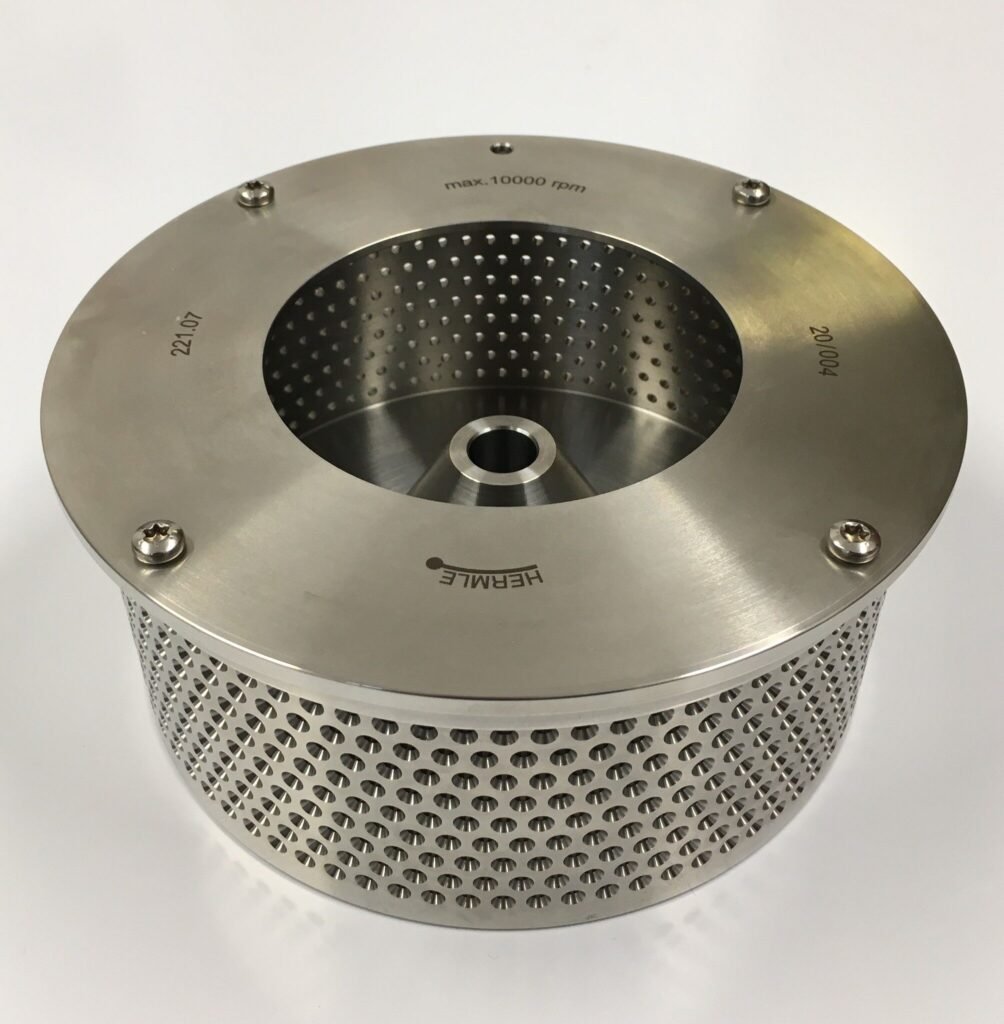

CENTRIFUGE BASKETS

Polyurethane (PU) centrifuge baskets are integral components utilized in various industries for the separation and dewatering of solids from liquid suspensions or slurries through centrifugal force. These baskets are meticulously engineered from polyurethane material, renowned for its exceptional durability, corrosion resistance, and wear properties, ensuring reliable performance in demanding industrial applications.

The benefits of PU centrifuge baskets are manifold. Firstly, their robust construction and abrasion resistance enable prolonged service life and minimal maintenance requirements, resulting in enhanced operational efficiency and cost savings for industrial processes. They withstand harsh operating conditions with ease, providing consistent and reliable performance in centrifugal separation applications, such as mining, wastewater treatment, and chemical processing.

Moreover, PU centrifuge baskets offer superior dewatering efficiency, facilitating the removal of moisture from solids with precision and accuracy. This results in improved product quality, reduced drying times, and increased throughput in downstream processes, contributing to overall process optimization and productivity.

Additionally, PU centrifuge baskets are lightweight and easy to handle, facilitating quick and hassle-free installation, maintenance, and replacement procedures. Their modular design allows for seamless integration into existing centrifuge systems, enhancing operational flexibility and adaptability.

Furthermore, PU centrifuge baskets are resistant to corrosion, chemicals, and temperature fluctuations, ensuring reliable performance and longevity in harsh industrial environments.

Overall, PU centrifuge baskets represent a cost-effective and reliable solution for industries seeking to improve separation efficiency, product quality, and operational reliability, making them a valuable offering from Adroit Engineering.

PIPO-II P U SCREENS

Polyurethane (PU) PIPO II screens are advanced screening panels utilized in various industries for efficient particle separation and classification. These screens are engineered from polyurethane material using the PIPO II (Polyurethane Injection, Polyurethane Out) manufacturing process, ensuring superior durability, flexibility, and performance in demanding industrial applications.

The benefits of PU PIPO II screens are substantial. Firstly, their high abrasion resistance and durability ensure extended service life and minimal maintenance requirements, resulting in reduced downtime and operational costs for industrial processes. They provide reliable and consistent screening performance, even in high-wear conditions encountered in mining, quarrying, and aggregate processing.

Moreover, PU PIPO II screens offer exceptional screening efficiency and accuracy, enabling precise separation of particles based on size, shape, and composition. This enhances product quality and consistency while optimizing process performance and throughput.

Additionally, PU PIPO II screens are lightweight and easy to handle, allowing for quick and hassle-free installation, maintenance, and replacement procedures. Their modular design facilitates seamless integration into existing screening equipment and systems, enhancing operational flexibility and productivity.

Furthermore, PU PIPO II screens are resistant to corrosion, chemicals, and temperature fluctuations, ensuring reliable performance in diverse industrial applications, including dry screening, wet screening, and dewatering processes.

Overall, PU PIPO II screens represent a cost-effective and reliable solution for industries seeking to improve screening efficiency, product quality, and operational reliability, making them a valuable offering from Adroit Engineering.

PIPO II MODULES

Polyurethane (PU) PIPO II modules are sophisticated screening solutions meticulously engineered for diverse industrial applications, offering unparalleled durability, efficiency, and versatility. These modules are manufactured using the innovative PIPO II (Polyurethane Injection, Polyurethane Out) process, ensuring optimal material properties and performance characteristics.

The benefits of PU PIPO II modules are manifold. Firstly, their exceptional abrasion resistance and robust construction ensure extended service life and minimal maintenance requirements, resulting in increased uptime and reduced operational costs for industrial processes. They provide reliable and consistent screening performance, even in challenging environments encountered in mining, quarrying, and aggregate processing.

Moreover, PU PIPO II modules offer superior screening efficiency and precision, enabling precise separation of particles based on size, shape, and composition. This enhances product quality and consistency while optimizing process performance and throughput, leading to improved productivity and profitability.

Additionally, PU PIPO II modules are lightweight and easy to handle, facilitating quick and hassle-free installation, maintenance, and replacement procedures. Their modular design allows for seamless integration into existing screening equipment and systems, enhancing operational flexibility and adaptability.

Furthermore, PU PIPO II modules are resistant to corrosion, chemicals, and temperature fluctuations, ensuring reliable performance in diverse industrial applications, including dry screening, wet screening, and dewatering processes.

Overall, PU PIPO II modules represent a cost-effective and reliable screening solution for industries seeking to enhance efficiency, product quality, and operational reliability, making them a valuable offering from Adroit Engineering.

POLY WEDGE

Polyurethane (PU) Poly Wedges are innovative components utilized in various industries for efficient screening and material separation applications. These wedges are meticulously engineered from high-quality polyurethane material, renowned for its exceptional durability, flexibility, and abrasion resistance, ensuring reliable performance in demanding industrial environments.

The benefits of PU Poly Wedges are significant. Firstly, their unique design and construction allow for precise and efficient screening of materials, resulting in improved product quality and consistency. They provide reliable and consistent performance, even in high-wear conditions encountered in mining, quarrying, and aggregate processing.

Moreover, PU Poly Wedges offer superior abrasion resistance and durability, ensuring extended service life and minimal maintenance requirements. This results in reduced downtime and operational costs for industrial processes, contributing to increased productivity and profitability.

Additionally, PU Poly Wedges are lightweight and easy to handle, facilitating quick and hassle-free installation, maintenance, and replacement procedures. Their modular design allows for seamless integration into existing screening equipment and systems, enhancing operational flexibility and adaptability.

Furthermore, PU Poly Wedges are resistant to corrosion, chemicals, and temperature fluctuations, ensuring reliable performance in diverse industrial applications, including dry screening, wet screening, and dewatering processes.

Overall, PU Poly Wedges represent a cost-effective and reliable solution for industries seeking to enhance screening efficiency, product quality, and operational reliability, making them a valuable offering from Adroit Engineering.

MINING EQUIPMENTS

GRIZZLY HOPPER

A Grizzly Hopper serves as a critical component in industrial processes, particularly in mining, quarrying, and aggregate handling operations. This specialized equipment consists of a robust hopper equipped with a series of sturdy bars or grids, known as grizzlies, positioned at the top. These grizzlies effectively pre-screen raw material before it enters downstream processing equipment such as crushers or conveyors.

The benefits of a Grizzly Hopper are significant. Firstly, it enhances operational efficiency by removing oversized or unwanted materials from the feed stream, preventing damage to downstream equipment and ensuring optimal performance. This results in reduced downtime, maintenance costs, and material wastage, ultimately improving overall productivity.

Moreover, Grizzly Hoppers improve workplace safety by effectively separating large rocks or debris from the feed material, minimizing the risk of accidents or equipment malfunctions caused by oversized objects entering processing equipment.

Additionally, Grizzly Hoppers offer versatility in application, accommodating various types of materials and operating conditions. They can be customized with different grizzly configurations and spacing options to suit specific material characteristics and processing requirements.

Furthermore, Grizzly Hoppers contribute to environmental sustainability by minimizing the need for manual sorting and reducing the amount of waste generated during the material handling process.

Overall, Grizzly Hoppers play a crucial role in optimizing material flow, protecting downstream equipment, and enhancing operational efficiency in industrial settings, making them an indispensable asset for Adroit Engineering’s comprehensive solutions.

JAW CRUSHER

A Jaw Crusher is a primary crushing machine widely utilized in various industries such as mining, quarrying, and construction. It consists of a fixed jaw and a movable jaw, with the movement of the latter creating a compressive force against the stationary jaw to crush the material fed into the chamber.

The benefits of a Jaw Crusher are manifold. Firstly, it offers efficient and reliable crushing of hard and abrasive materials, making it ideal for processing a wide range of materials, including ores, minerals, and aggregates. This results in improved product quality and consistency, enhancing downstream processing efficiency.

Moreover, Jaw Crushers are designed for high throughput and low operating costs, with robust construction and durable components ensuring long-term reliability and performance. They provide consistent particle size reduction, reducing the need for secondary crushing stages and minimizing energy consumption.

Additionally, Jaw Crushers offer versatility in application, capable of handling various types of feed materials and operating conditions. They can be customized with different jaw profiles and chamber geometries to suit specific material characteristics and processing requirements.

Furthermore, Jaw Crushers contribute to workplace safety by incorporating features such as hydraulic adjustment systems and overload protection mechanisms, ensuring safe and efficient operation.

Overall, Jaw Crushers play a pivotal role in primary crushing operations, providing essential capabilities for material processing and production in industrial settings, making them a valuable offering from Adroit Engineering.

VIBRATING SCREEN

A Vibrating Screen is a versatile and essential piece of equipment used across various industries for efficient particle separation and sizing. It consists of a screening surface, typically made of wire mesh or perforated plates, that vibrates rapidly to facilitate the separation of particles based on size, shape, and composition.

The benefits of Vibrating Screens are manifold. Firstly, they offer high screening efficiency, allowing for precise and accurate separation of particles across a wide range of sizes. This results in improved product quality and consistency, enhancing downstream processes and overall operational efficiency.

Moreover, Vibrating Screens are highly customizable, with options for different screening surfaces, incline angles, and vibration patterns to suit specific material characteristics and processing requirements. This versatility enables them to handle a variety of materials, from fine powders to coarse aggregates, with ease.

Additionally, Vibrating Screens are designed for durability and reliability, with robust construction and heavy-duty components ensuring long-term performance in demanding industrial environments. They require minimal maintenance and downtime, contributing to increased productivity and cost savings for businesses.

Furthermore, Vibrating Screens contribute to workplace safety by incorporating features such as dust suppression systems and protective guards, ensuring safe and efficient operation.

Overall, Vibrating Screens play a crucial role in material handling and processing operations, providing essential capabilities for particle separation and sizing in industrial settings, making them a valuable offering from Adroit Engineering.

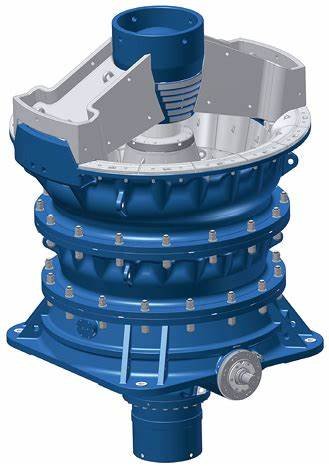

CONE CRUSHER

A Cone Crusher is a versatile and efficient crushing machine widely used in industries such as mining, quarrying, and construction. It features a conical crushing chamber with a rotating mantle and a concave liner, allowing for efficient compression crushing of hard and abrasive materials.

The benefits of a cone Crusher are manifold. Firstly, it offers high crushing efficiency and uniform particle size distribution, resulting in improved product quality and consistency. This ensures that downstream processes such as milling or screening operate with optimal efficiency.

Moreover, Cone Crushers are designed for versatility, capable of handling a wide range of materials and operating conditions. They can be equipped with different chamber configurations, mantle designs, and eccentric speeds to suit specific material characteristics and processing requirements, providing flexibility in application.

Additionally, Cone Crushers are renowned for their reliability and durability, with robust construction and heavy-duty components ensuring long-term performance in demanding industrial environments. They require minimal maintenance and downtime, contributing to increased productivity and cost savings for businesses.

Furthermore, Cone Crushers incorporate safety features such as hydraulic overload protection and automatic tramp release systems, ensuring safe and efficient operation while minimizing the risk of damage to the crusher and surrounding equipment.

Overall, Cone Crushers play a crucial role in primary and secondary crushing operations, providing essential capabilities for material processing and production in industrial settings, making them a valuable offering from Adroit Engineering.

HYDRAULIC CONE

Hydraulic cones are pivotal components in various industries, offering unparalleled efficiency and reliability in material processing and crushing applications. These advanced systems leverage hydraulic technology to optimize cone crusher performance, enhancing productivity and ensuring precise control over crushing operations.

The benefits of hydraulic cones are manifold. Firstly, they provide superior crushing efficiency and particle size distribution, resulting in improved product quality and consistency. Hydraulic adjustment mechanisms enable quick and precise control over the crusher’s settings, allowing operators to adapt to changing feed conditions and optimize performance for maximum throughput.

Moreover, hydraulic cones offer enhanced safety features, including hydraulic overload protection and automatic cavity clearing, mitigating the risk of damage to the crusher and ensuring safe and efficient operation in challenging environments.

Additionally, hydraulic cones are designed for durability and longevity, with robust construction and high-quality components ensuring reliable performance in demanding industrial settings. They require minimal maintenance and downtime, contributing to increased operational efficiency and cost savings for businesses.

Furthermore, hydraulic cones offer versatility in application, capable of handling a wide range of materials and operating conditions. They can be customized with various chamber configurations, mantle designs, and hydraulic systems to suit specific crushing requirements and processing needs.

Overall, hydraulic cones represent a state-of-the-art solution for optimizing crushing operations in industries such as mining, quarrying, and construction, making them a valuable offering from Adroit Engineering.

VERTICAL SHAFT IMPACTOR

Vertical Shaft Impactors (VSIs) are pivotal machines utilized in various industries for efficient crushing and shaping of aggregate materials. These machines feature a vertical shaft equipped with rotating impellers or hammers that propel material against a stationary anvil or impact surface, resulting in high-speed impact crushing.

The benefits of Vertical Shaft Impactors are manifold. Firstly, they offer superior crushing efficiency and particle shaping capabilities, producing uniform and well-graded aggregate products with minimal fines. This enhances the quality and consistency of final products, making them suitable for a wide range of applications in industries such as construction, mining, and recycling.

Moreover, Vertical Shaft Impactors provide versatility in material processing, capable of handling various types of rock, ore, and other materials with different hardness and abrasiveness. They can be configured with different rotor designs, speeds, and chamber configurations to optimize crushing performance for specific applications and feed materials.

Additionally, Vertical Shaft Impactors are designed for durability and reliability, with robust construction and high-quality components ensuring long-term performance in demanding industrial environments. They require minimal maintenance and downtime, contributing to increased productivity and cost savings for businesses.

Furthermore, Vertical Shaft Impactors offer energy efficiency and environmental benefits, with advanced rotor designs and efficient drive systems reducing energy consumption and emissions compared to traditional crushing methods.

Overall, Vertical Shaft Impactors play a crucial role in material processing and shaping operations, providing essential capabilities for producing high-quality aggregate products in industrial settings, making them a valuable offering from Adroit Engineering.

.

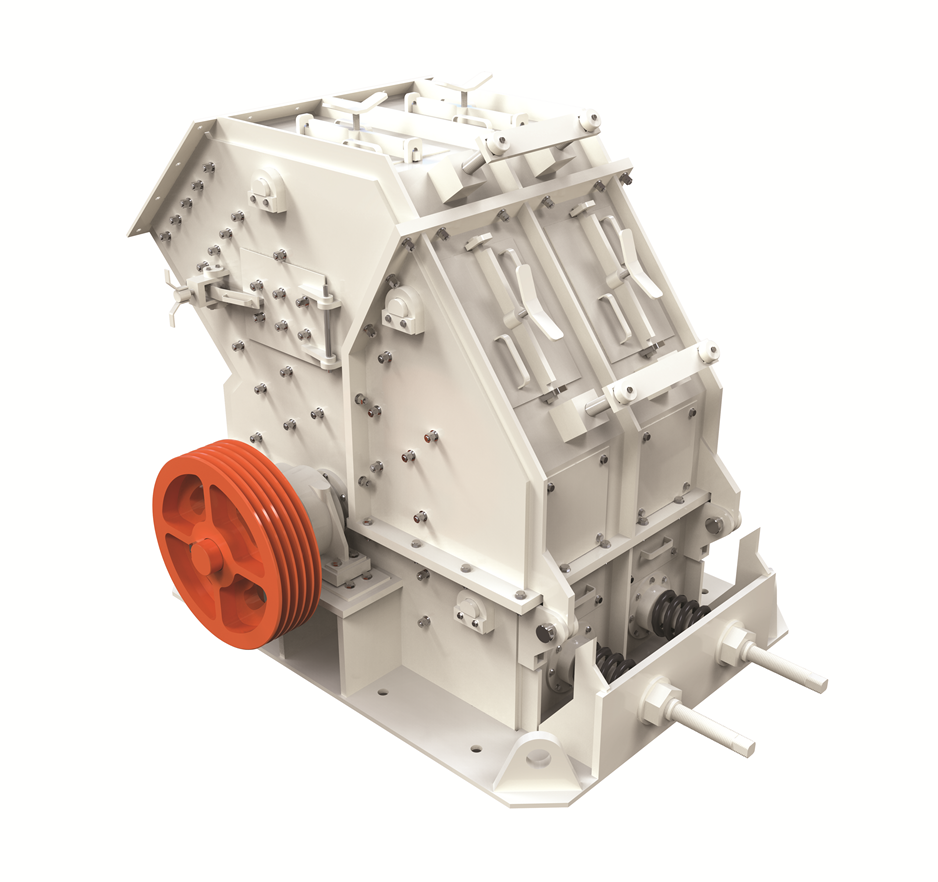

HORIZONTAL SHAFT IMPACTOR

Horizontal Shaft Impactors (HSIs) are essential machines employed in various industries for efficient and versatile crushing of aggregate materials. These machines feature a horizontal shaft equipped with hammers or blow bars that impact the feed material against breaker plates or anvils, resulting in high-speed impact crushing.

The benefits of Horizontal Shaft Impactors are manifold. Firstly, they offer exceptional crushing efficiency and versatility, capable of producing a wide range of particle sizes and shapes with minimal fines. This enables the production of high-quality aggregate products suitable for diverse applications in industries such as mining, construction, and recycling.

Moreover, Horizontal Shaft Impactors provide flexibility in material processing, accommodating various types of rock, ore, and other materials with different hardness and abrasiveness. They can be configured with different rotor designs, speeds, and chamber configurations to optimize crushing performance for specific applications and feed materials.

Additionally, Horizontal Shaft Impactors are designed for durability and reliability, with robust construction and high-quality components ensuring long-term performance in demanding industrial environments. They require minimal maintenance and downtime, contributing to increased productivity and cost savings for businesses.

Furthermore, Horizontal Shaft Impactors offer energy efficiency and environmental benefits, with efficient rotor designs and drive systems reducing energy consumption and emissions compared to traditional crushing methods.

Overall, Horizontal Shaft Impactors play a crucial role in material processing and crushing operations, providing essential capabilities for producing high-quality aggregate products in industrial settings, making them a valuable offering from Adroit Engineering.

WE ALSO SELL INDUSTRIAL GEARS & PUMPS